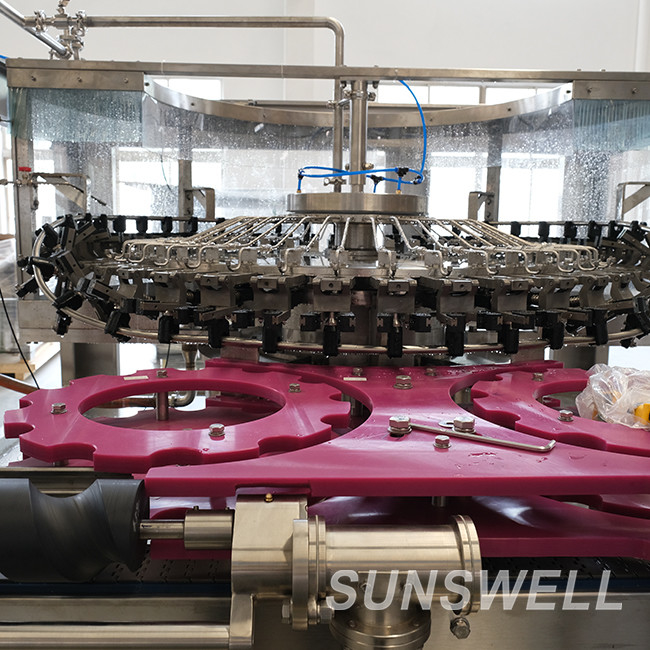

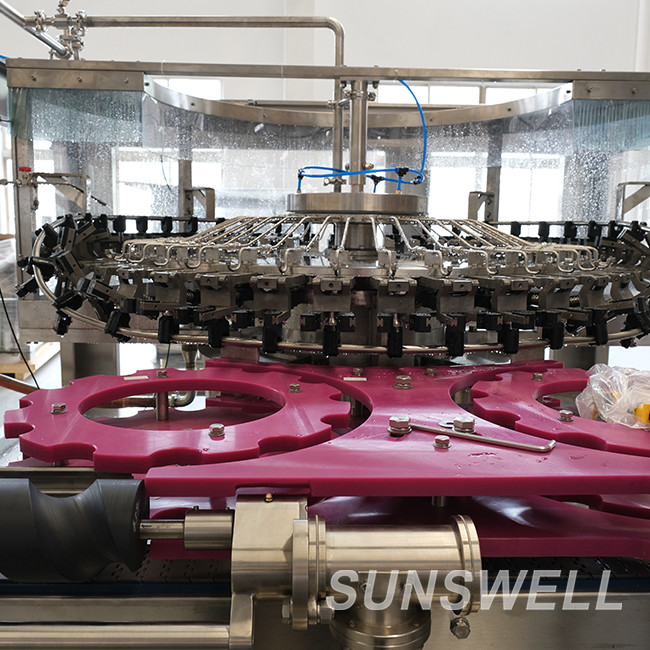

It’s composed by filling tank, filling valve, control cam, elevated cylinder, and clock cover valve opener and up and down dispenser. When it’s tested there is bottle, the valve opener opens the control pole and then

CO2 opens. When the bottle pressure set the same pressure as tank interior, the main liquid passage opens automatically. The main liquid exhaust CO2, while it returns to the needle whole and air exhaust pipe. When the continuous liquid seal the air pipe, the bottle pressure is higher than the tank pressure. Under the pressure effect, the filling valve stops. After the filling finish, shut up the filling valve and let the CO2 out through the exhaust cam. (Don’t exhaust too fast, otherwise easy to get foam.

Equipped with CIP pipeline, main liquid pipe and air in pipe ensure the filling, cleaning. There is level sensor, safety valve,thermo meter and pressure gauge on the level tank. Clock cover, control pole is also fixed there.

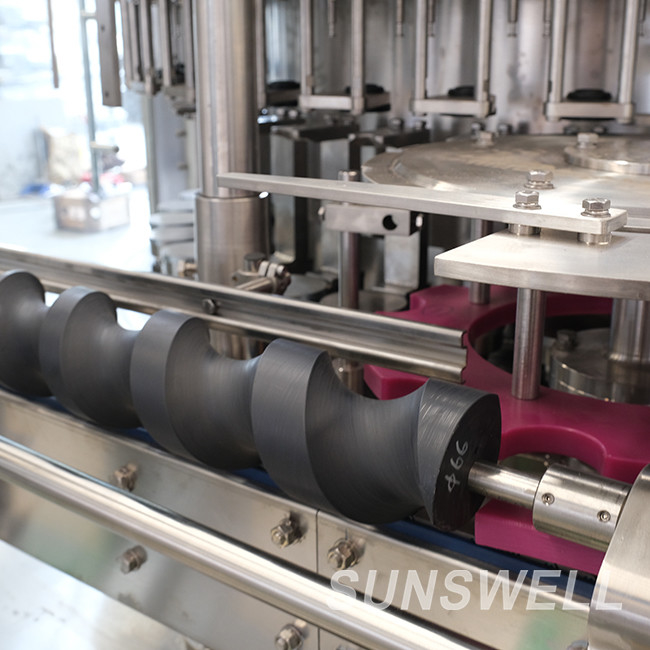

The mixed material is transferred from filling valve to the tank. Filling liquid is controlled by the air return pipe; air return pipe is equipped with the umbrella structure, easier for the material filling. It also adopts the screw joint, easier for dismantle, only change the air pipe length when it needs the level adjustment. Air charge valve pole shut the CO2 return passage.Outer control pole life the charge valve and then opens the air charge/air return passage. Exhaust is preventing the material form making after filling.

Leave a Message

We will call you back soon!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters!

Please check your E-mail!

Please check your E-mail!

SUBMIT

More information facilitates better communication.

mr

- mr

- mrs

OK

Submitted successfully!

We will call you back soon!

OK

Leave a Message

We will call you back soon!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters!

Please check your E-mail!

Please check your E-mail!

SUBMIT